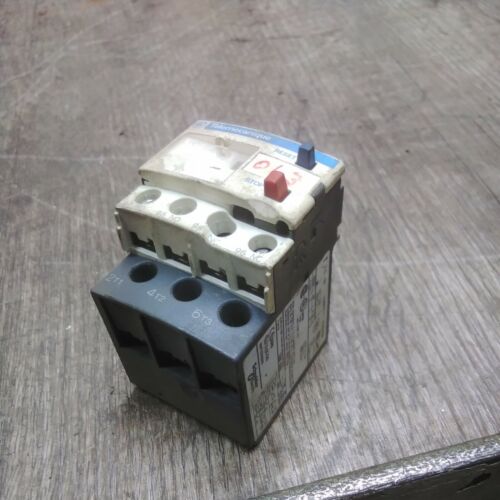

This product page details the Schneider Electric TeSys LR2-D thermal overload relay, a precision motor protection device designed for reliable three-phase motor applications. Featuring an adjustable current setting range, 3-pole configuration, Class 10A trip curve, and screw terminals, this relay provides comprehensive protection against motor overload conditions in industrial and commercial environments.

Overview of the Thermal Overload Relay

The TeSys LR2-D thermal overload relay serves as a critical safeguard in motor control circuits. Because it utilizes precision bimetal technology to monitor motor current, it effectively prevents motor damage from excessive current draw while allowing for normal starting currents and temporary overload conditions that occur during regular operation.

Key Features and Technical Specifications

This motor protection device is engineered for precision and reliability. Therefore, here are its essential characteristics:

- Current Setting: Adjustable current range for precise motor matching

- Poles: 3-pole configuration for three-phase motor protection

- Trip Class: Class 10A for standard motor protection applications

- Terminals: Screw terminals for secure, reliable connections

- Mounting: Direct mounting to compatible TeSys contactors

- Reset: Manual reset function with trip indication

- Ambient Compensation: Temperature compensated for stable operation

- Standards: Compliant with IEC/EN 60947-4-1 standards

Typical Applications and Use Cases

The reliable protection of this thermal overload relay makes it suitable for various motor control applications. For example, it is commonly used for:

- Three-phase motor protection in industrial machinery

- Pump and fan motor control systems

- Conveyor and material handling equipment

- HVAC system compressor and fan motors

- Machine tool and manufacturing equipment

- Processing and packaging machinery

- Commercial building mechanical systems

For complete motor control solutions, explore our range of compatible TeSys contactors and motor starters designed to work with LR2-D overload relays.

Why Choose the TeSys LR2-D Thermal Overload Relay?

Selecting the Schneider Electric TeSys LR2-D thermal overload relay provides significant advantages for motor protection applications. Firstly, the adjustable current setting allows precise calibration to match specific motor nameplate ratings, ensuring optimal protection without nuisance tripping. Secondly, the Class 10A trip curve provides fast protection for standard motors while allowing for normal starting currents. Consequently, you achieve precise motor protection that balances operational flexibility with equipment safety.

Installation and Setting Guidelines

Proper installation and calibration of this thermal overload relay are crucial for effective motor protection. Mount the relay directly to a compatible TeSys contactor, ensuring secure mechanical and electrical connection. Set the current adjustment dial to match the motor’s exact full-load current as specified on the motor nameplate. Furthermore, the screw terminals provide reliable connections for both power circuits and auxiliary contacts, while the manual reset function ensures safe operation by requiring intentional reset after a trip condition.

For detailed technical specifications and application guidelines, consult the comprehensive Schneider Electric TeSys LR2-D documentation.

Protect Your Motor Investments Today

In summary, the Schneider Electric TeSys LR2-D thermal overload relay with its adjustable current setting and Class 10A protection represents a reliable solution for three-phase motor protection. Finally, by incorporating this precision protection device into your motor control systems, you ensure equipment safety, reduce downtime, and extend motor lifespan in your industrial and commercial applications.