Empowering Wilmar Rice Tanzania’s Growth with Expert Solutions

As experienced electrical contractors, IAESTZ is proud to highlight our involvement in expanding Wilmar Rice’s production line in Morogoro. This complex project required advanced electrical systems and infrastructure to support the growth of one of Tanzania’s leading rice processing facilities.

Our team provided end-to-end electrical solutions, including installing, testing, and commissioning key systems. All done to meet the client’s current and future operational needs. Here’s a closer look at the scope of work we delivered:

33kV High-Tension Cable System

One of the primary tasks was the installation of a 33kV high-tension (HT) cable system. This cable was used to ensure robust and reliable power transmission across the expanded facility. We installed and terminated a 3-core 300 sq.mm. Aluminum armored HT cable from the gas-insulated switchgear (GIS) to the transformer.

Transformer Installation

The heart of any industrial power system is its transformer, and we were responsible for installing a 2500kVA synthetic ester oil-type transformer (33kV/0.433kV). This outdoor KNAN transformer meets all modern safety and performance standards (IEC 60076).

Primary termination with high-tension 33kV cables and secondary termination using a busduct system rated for 4000A.

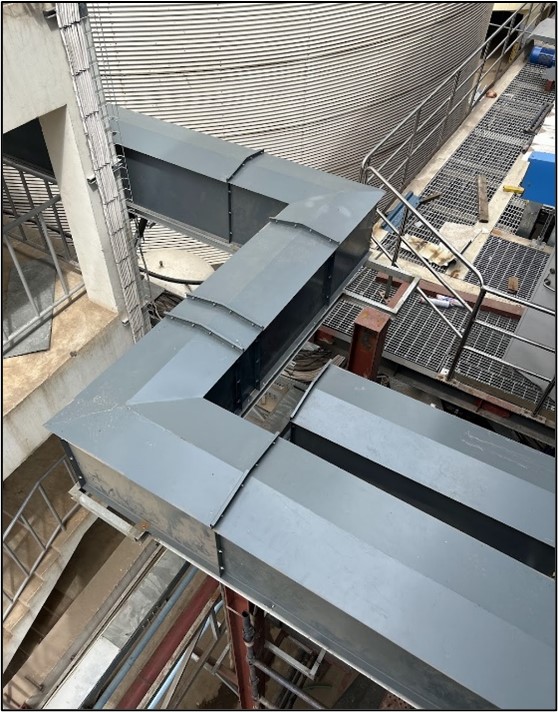

Busduct Installation

For efficient power distribution, we installed a 4000A Aluminum alloy busduct system, securely connecting the transformer to the Power Control Center (PCC). We built this system to be able to handle high current loads and protect against environmental factors.

We also installed IP56-rated canopies for outdoor protection of the bus duct.

Low Voltage Power Distribution and Motor Control Centre (MCC) Panels

Our team installed and commissioned several critical LV panels, including PCC, APFC, MCC, PLC, Remote I/O, PDB, UPSDB, and Lighting Distribution Boards. Key highlights include:

- Installation of the PCC Panel handling a 4000A load, complete with bus duct entry and cable termination.

- APFC Panel installation with 500 KVAR capacity and detuned reactors to regulate reactive power.

- MCC Panels installed near the paddy silo for motor control and protection, while the PLC and Remote I/O Panels ensured plant automation and communication through SCADA.

All systems were tested and commissioned to meet the highest industry standards for reliability and operational integrity.

UPS Installation

To prevent interruptions in critical operations, we installed two 30kVA Uninterruptible Power Supply (UPS) systems. These systems power essential equipment, including PLCs, Remote I/O, server panels, console desks, and color sorter machines.

Cable Laying and termination

Cable laying and termination are vital processes in any electrical installation, ensuring efficient power distribution and system reliability. In this project, the process involved carefully routing various types of cables from and to various locations. Power, control, and communication cables from the LT Panel Room to multiple key panels, such as the PCC, APFC, MCC, PLC, Remote I/O, PDB, UPSDB, and Lighting Distribution Boards.

High-quality copper and aluminum cables were used, selected based on load capacity and environmental conditions. We performed the termination with precision, ensuring secure connections and proper alignment. This is critical for minimizing voltage drop and ensuring optimal system performance. Testing and commissioning ensured that all connections were correctly insulated, continuous, and able to perform efficiently under load, guaranteeing the overall integrity of the electrical system.

LED Lighting and Controls

To prioritize energy efficiency and safety, we upgraded the facility’s lighting system by installing Philips LED lights, complete with emergency backup options for critical areas. We also installed control panels to efficiently manage the lighting and other production systems

Remarks

Through this comprehensive range of services, we ensured Wilmar Rice Tanzania Limited’s new production line operates with enhanced safety, efficiency, and reliability. Our expertise in electrical installations and commitment to the highest standards support the continued growth of industrial projects across Tanzania.